How to Produce Bamboo Fiber: A Comprehensive Guide from Harvest to Fabric?

How to Produce Bamboo Fiber: A Comprehensive Guide from Harvest to Fabric?

Bamboo fiber has emerged as a popular choice in the textile industry due to its sustainability and unique properties. This guide will take you through the entire process of producing bamboo fiber, from harvesting the bamboo to creating the final fabric.

By understanding these steps, you can appreciate the versatility and environmental benefits of bamboo fiber.

Choosing Bamboo: Origin and Characteristics

Varieties and Origin

Bamboo fiber production begins with selecting the right bamboo species. Moso Bamboo (Phyllostachys edulis) is primarily cultivated in Southern China and Southeast Asia.

On the other hand, Indian Bamboo (Bambusa bambos) is commonly grown in South Asia.

Each variety plays a crucial role in determining the quality and characteristics of the resulting fiber.

Characteristics

Bamboo fiber is highly valued for its rapid growth, high fiber content, and exceptional durability. These attributes make bamboo an excellent choice for a range of textile applications, offering both environmental and functional benefits.

For instance, bamboo’s growth rate allows for more sustainable harvesting compared to slower-growing plants.

Bamboo Material Processing Steps

Breaking Down Bamboo

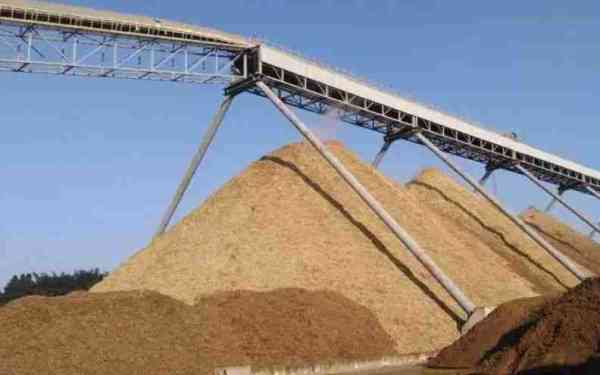

To begin processing bamboo, the stalks are mechanically ground into small particles using specialized equipment, such as grinders or hammer mills.

Ensuring that the particle sizes are consistent is essential for optimizing efficiency in the following stages. Therefore, proper processing techniques are critical to achieving high-quality bamboo fiber.

Storage Conditions

After processing, bamboo should be stored in dry, well-ventilated environments. This storage practice helps prevent moisture buildup and mold growth, which could otherwise degrade the quality of the bamboo fiber.

Consequently, maintaining proper storage conditions is vital for preserving the fiber’s integrity.

Preparing Bamboo Pulp

Chemical Method

In preparing bamboo pulp, alkaline or acid-based solutions are utilized to break down lignin and extract cellulose fibers. This method effectively isolates the fibers needed for producing high-quality bamboo fabric.

Additionally, this chemical process allows for the extraction of pure cellulose, which is essential for achieving the desired fabric properties.

Mechanical Method

Alternatively, bamboo pulp can be prepared using mechanical processes, such as grinding or refining. These methods separate the bamboo fibers without relying on chemicals.

As a result, this approach offers a more natural option for pulp preparation, catering to those who prefer less chemical intervention.

Extracting and Processing Bamboo Fibers

Chemical Extraction

During chemical extraction, bamboo pulp is dissolved in a chemical solution to isolate cellulose fibers. These fibers are then spun into yarn, ready for textile production.

This process is crucial for creating high-quality yarn that meets industry standards.

Mechanical Extraction

Mechanical extraction involves breaking down bamboo into fibers through physical processes. This method is suitable for producing fibers used in various textile applications.

It offers a different approach compared to chemical extraction, contributing to the versatility of bamboo fiber production.

Weaving Bamboo Fibers into Fabric

Spinning

Once the bamboo fibers are prepared, they are twisted and stretched to form yarn. This yarn is essential for weaving or knitting the bamboo fabric.

Spinning transforms the raw fibers into a usable form, setting the stage for the creation of high-quality fabric.

Weaving or Knitting

The yarn is then interlaced to create fabric known for its softness, breathability, and moisture-wicking properties. This fabric is ideal for various clothing and textile products. Notably, bamboo fabric’s characteristics make it a preferred choice for both everyday wear and specialized applications.

Fabric Properties

Bamboo fiber fabric is praised for its superior comfort, breathability, and ability to manage moisture. These qualities enhance the fabric’s performance and make it a desirable material for diverse uses.

As a result, bamboo fabric offers a combination of comfort and functionality that sets it apart from other textiles.

Finishing and Manufacturing

Dyeing and Printing

Eco-friendly dyes and printing techniques are used to add color and patterns to bamboo fabric. These sustainable methods ensure that the final product meets both aesthetic and environmental standards.

Consequently, the finished fabric not only looks good but also aligns with eco-friendly practices.

Cutting and Sewing

The fabric is then cut and sewn into garments or other products. High-quality craftsmanship ensures that the finished items are both functional and stylish.

This attention to detail is crucial for creating products that meet consumer expectations and industry standards

Comparison with Other Fabrics

When compared to traditional fabrics like cotton and synthetic fibers, bamboo fiber offers several advantages. Bamboo is more environmentally friendly, requiring fewer resources and less chemical intervention.

In terms of comfort, bamboo fabric surpasses cotton with its softness and moisture-wicking properties. Additionally, bamboo fiber is more durable and less prone to wrinkling compared to cotton.

While synthetic fibers can be durable and low-maintenance, they lack the natural breathability and comfort of bamboo fabric. As the demand for sustainable textiles grows, bamboo fiber presents a compelling alternative.

Conclusion

In summary, bamboo fiber represents a significant advancement in sustainable textiles, combining environmental responsibility with superior performance.

By choosing bamboo, we support innovative textile solutions that contribute to a healthier planet. As industries and consumers increasingly embrace bamboo fiber, it plays a pivotal role in shaping a more sustainable future for fashion and textiles.

Portfolio Categories

Share This Post, Choose Your Platform!

Quick Glance

- How to Produce Bamboo Fiber: A Comprehensive Guide from Harvest to Fabric?